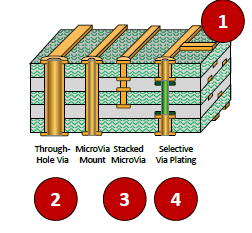

The traditional subtractive etch process for manufacturing printed circuit boards becomes much less reliable when working with features that are sub 1 mil. There has been a new additive process developed that uses a precursor ink to break through these barriers and meets four market needs:

1. Fine line (< 25 micron) Additive (Rigid and flex PCB)

- Precursor ink makes the additive process practical

- Additive process makes the fine lines practical

- This process works well with existing manufacturing equipment

- Cost savings over conventional processing can be 35%-60%

2. Via excellence (Rigid PCB)

- Precursor ink is the key advantage

- Reduces electroless usage by 60% or more

- Reduces the use of water by 60% or more

- Lower cost than conventional processing

3. Stacked microvia excellence (Rigid/Flex PCB)

- Better results than conventional processing

- Precursor ink is the key advantage

- Eliminates the need for sequential lamination

- Cost savings can be 20%-30%

4. Selective via plating (Multilayer rigid PCB)

- Precursor ink and ink blocker are the keys

- Eliminates the need for sequential lamination processing

- Cost savings can be 20%-60%

This process can be used as a stand-alone technology or in conjunction with the traditional subtractive etch process. Please contact us if you are interested in learning more!